HealTech™ solutions enable to build composites with reduced maintenance costs and extended lifetimes of final products

HealTech™ is a technology allowing an ultra-fast and easy repair to extend the lifetime of composite parts, and reduce their CO2 emissions.

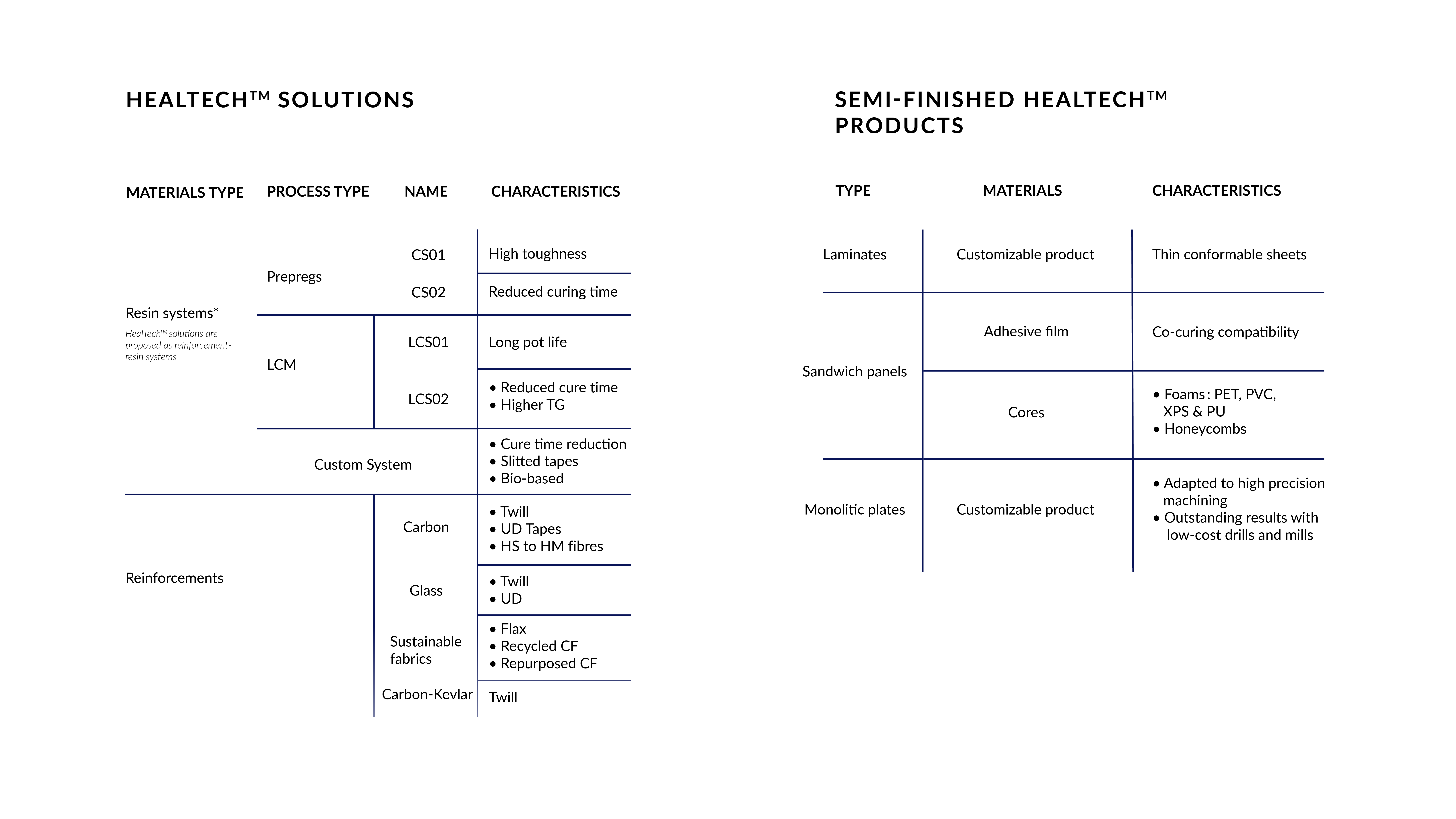

CompPair’s first product family is available as prepregs with different fibers and architectures. These products are compatible with current prepreg production processes. In addition, CompPair portfolio of solutions include Liquid Composites Moulding (LCM) capacities.

Using HealTech™ prepregs brings several benefits to manufacturers, end-users and the planet. Benefits include lowered maintenance and production costs, a 400 times faster repair, production defects reduction, downtime reduction, improved operational efficiencies and a largely improved life-cycle analysis.

By helping our clients build better composite products that last longer and produce less waste, we provide a clear added value to the consumers while drastically reducing the carbon footprint of composite structures.

CompPair’s vision is to bring full circularity to the composites industry.

Our mission is to help manufacturers, consumers, and the planet.

Composite structures built using HealTech™prepregs have an intrinsic healing capacity. Composite parts that have suffered matrix damage events can be repaired in-stitu ina couple minutes thanks to the prepreg technology.

The healing process is very simple. The damaged area of the composite part needs to be heated at moderate temperature (100-150°C), which can be done using a heat gun, a heated blanket, an oven, etc. After a couple minutes, the part while have regained its structure and properties and can be used once again.

Contrary to current repair processes, which may compromise the integrity of the fibres (creating a weak spot) and change the weight and profile of the products (altering their performances), repair with HealTech™ results in a renewed composite structure. Recovering 100% of mechanical properties after repair, the structure also maintains its integrity, profile, and weight.

HealTech™ solutions help clients, consumers and the planet.

HealTech™ is a thermoset-based resin system giving FRPs the ability to heal cracks and delaminations in 1 minute by locally heating the part in a range of 100°C-150°C. HealTech™ is suitable for autoclave, out-of-autoclave, and press curing, and in a range of composite processes, including prepregs and liquid solutions. CompPair continuously develops new solutions compatible with various manufacturing processes and adapted to extended composite applications.

– Technical Manager of a major composites manufacturer